Max H.

Journal Entries:

8.22.25

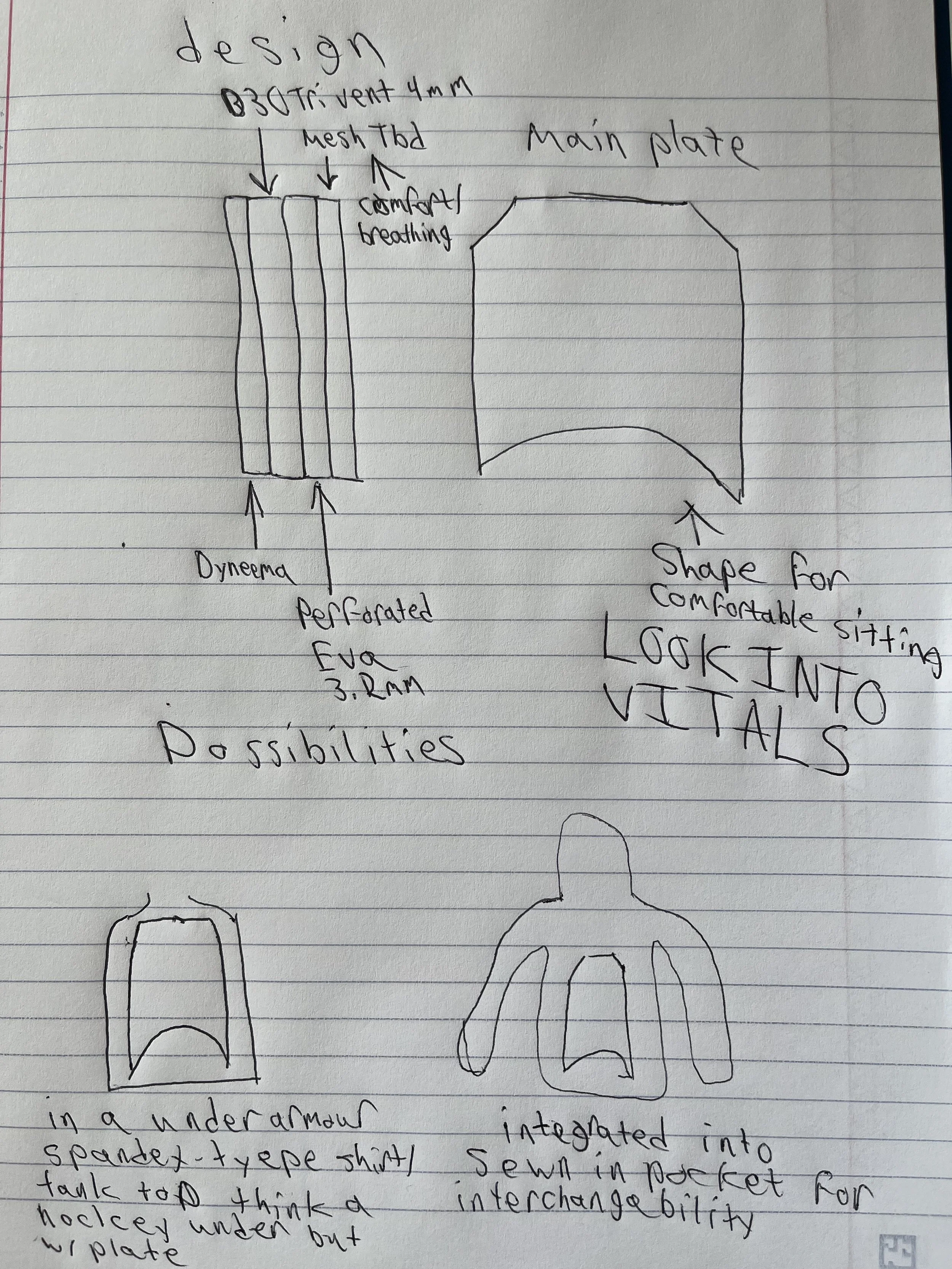

Today I brainstormed ideas for my WISRD project and talked with Megan about possible materials for my body armour design. After I finished brainstorming, I sketched out forms and layers for my possible design. Additionally, started work on my researcher profile.

8.25-29.25

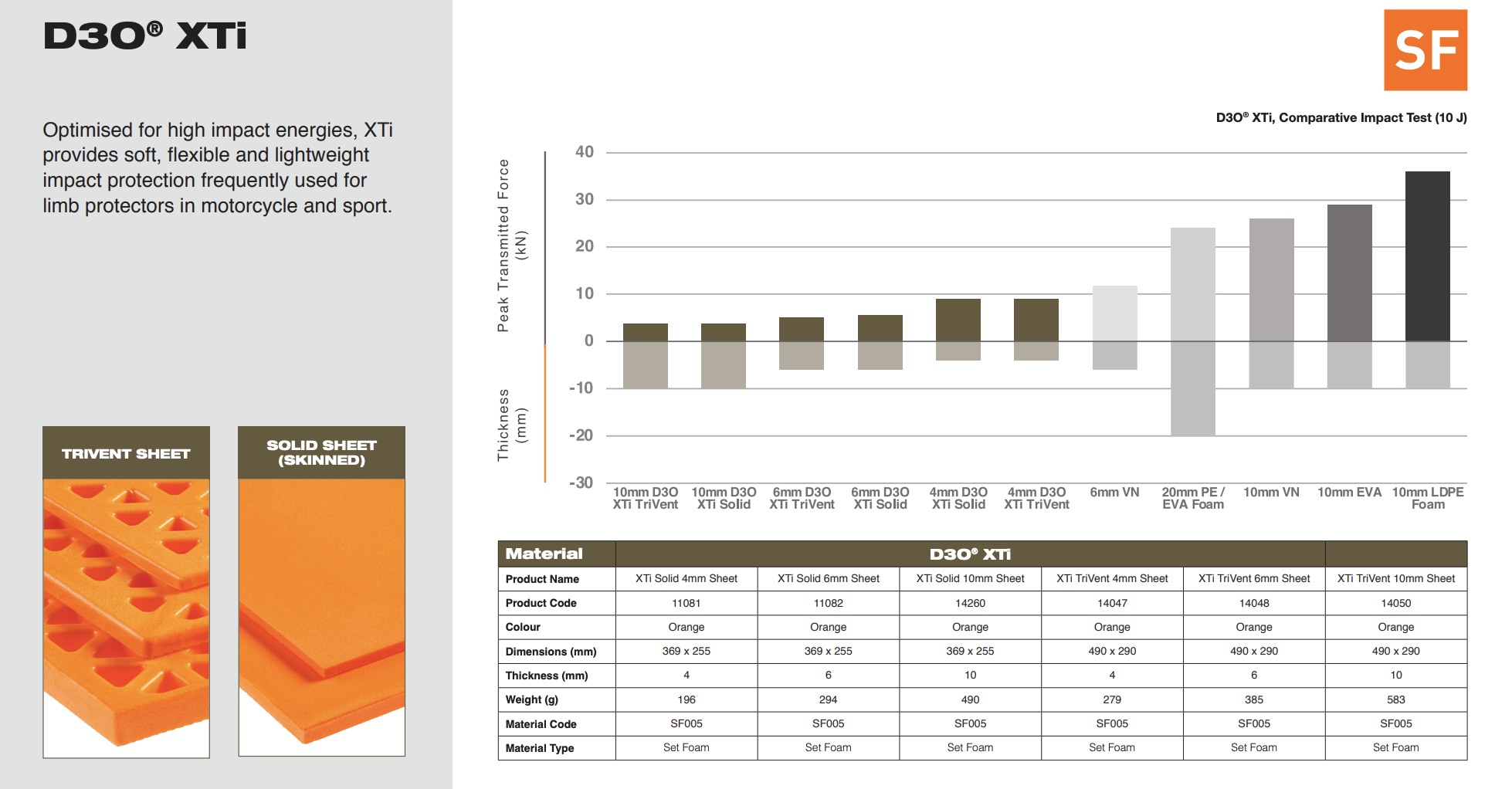

This week, I completed my researcher profile and linked it to my WISRD page. In the future, I need to remember to take pictures of my work to add to this profile. I also researched different variants of d3o and decided on a 4mm TriVent XTI sheet. This version will provide a good cushion and protection while also having ventilation. On Thursday, I learned how to solder and finished soldering a light-up rocket. The solar cell and LED ended up not working, so I tried to troubleshoot, but I could not get them to work. On Friday, I talked with Matt Lucas about D30, its properties, and how it could be implemented into my body armour. He additionally suggested a material called Dyneema, which is much stronger than steel and is used for rock climbing and fabric on sailboats. At the end of class, I asked Megan to order the sheet of D3O and a sample size of the Dyneema fabric.

Entry #3: 9.2-5.25

On Tuesday I practiced my soldering again. This time I chose a more difficult item with more components and a higher count of solders I had to complete. On another hand Megan ordered my D30 and Dyneema which should both be coming some time next week. My only problem now is to fins a way do disperse the energy once it hits the D30, so I decided to add a layer of EVA foam behind the D30 to take care of the excess energy. I will perforate the EVA in the same pattern as the D30 to promote good air flow. Behind the EVA I will add a layer of spacer mesh to ahieve a greater breatheability. A new idea that I had was to put the bodyarmor into a hoodie which would be the only reason I would not need to add a piece of mesh behind the reast of the foam and fabric layers. This is because there would already be a pocket sewn into the hoodie to keep the plate in place. On Friday I talked with Matt again about secure stitches I could use for the pocket and how I would begin to make a hoodie.

Entry #4 9.8-12.25

This week I built a full size model of my body armor using poster board. This model was not meant to display thickness it was just to get an idea of size and shape. I decided on a size of 9”x10 1/2”, but then had to compensate by trimming down slightly when shaping the top of the D30. I did all of the cutting with and X-ACTO knife, and found a paint marker or Sharpie to mark the lines. After our conversation last week Matt sent me clothing templates and I talked with him about how I would use these and he suggested printing them on a poster printer. For Dark Matter Day I chose to make electro magnets by wrapping copper wire around an iron nail. The wire has to be coated, but the ends have to be uncoated. For this I just took some sandpaper and when you see there is no more coating then you can stop. To power the magnet I used a AA battery and touched the two ends of the wire to the battery. If the magnet does not work then the core is either not iron or there is not enough wire. The last thing that I did this week was choose my Inquirer topic which is the Alternating Current electric motor developed by Nikola Tesla and used in Tesla cars today.

A list of all my materials and links to where I bought them:

October:

During October, I only worked on electromagnets for my dark matter day project. This underwent several phases of testing different battery combinations for strength. What I landed on as the easiest and strongest was a nine-volt battery. Some problems that I ran into were the heat of the wire while the current was running through the battery. To fix this, the application of the wire to the battery had to be brief, and I also wrapped the battery in electrical tape to insulate it. Another way that this could be solved, although I could not get it to work, was to use a switch. The problem that I ran into with this is that when the switch was off, current would run through it, and when the switch was on, it would do nothing. Some ways to troubleshoot this would be to use a flip switch instead of a temporary one. This would not only solve the problem of heat, but it would also solve the problem of ease of use, because pressing the button would activate the magnet and it would not require the manual connection of both sides.

11.3-14.25

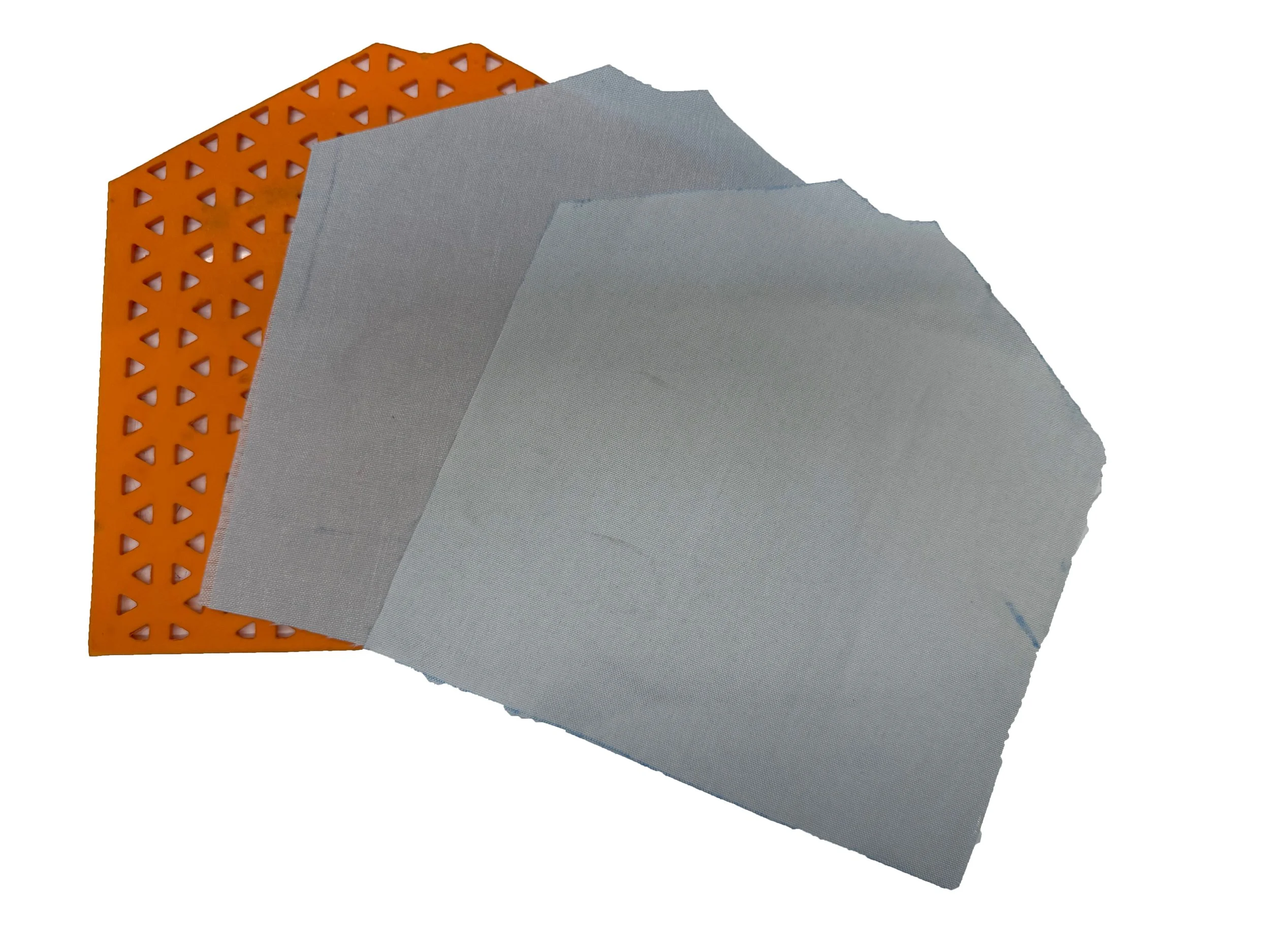

In this two weeks a lot happened on the third I got my shears which allowed me to cut the Dyneema more effectively which is a big step in my production process. I also found that the Glowforge is an extremely effective way of cutting the Dyneema and it even burns the ends melting them together. The full assembly of a plate lead to some preliminary testing. I stabbed the plate with a variety of different objects including scissors, a chisel, and an X-acto knife. The only full penetrations came against the X-acto knife and through the ventilation holes. For this reason the holes will be fazed out in future prototypes and a solid sheet of d3o will be used. A successful form of securing the Dyneema to the d3o is super glue, but I will be testing other methods in the future. Because of this I also requested some super glue and unperforated d3o. Because of my testing I decided against including any kind of foam backing because if it was as thin as I planned there would be little to no change in effectiveness or absorption. OUtside of my project I worked on my Inquirer article and my poster for the fall poster session.

1.6.26

Three things that I want to accomplish this semester are completing the rest of my project and testing the final product. The second and third things that I want to accomplish are collaborative. I want to keep learning how to solder with Niko and continue to make new circuits. The final thing that I want to accomplish is helping other WISRDs with their projects. A piece of advice that I want to implement this semester is not to use my WISRD period for out of class work.

1.7-14.26

January 2026

This month, I worked to create a WISRD sign. This took the entire month and was very challenging, and had many setbacks with components failing, breaking, and human errors. I started by stringing together the LED noodles, which allowed me to figure out how powerful the battery should be. I ended up landing on 45 volts, which gave some time before the power would decrease. Additionally attatching the LEDs was difficult, and I have not found a better way other than soldering them and then squeezing the LEDs together with pliers. The lights also had to be sequenced positive side to negative side, which added time to the project, with testing of lights occurring for every LED. In the final stages of production, many errors occurred, including accidentally punctured and broken LEDs. This lead required replacing three LEDs. The final issue that occurred was a blown-out resistor. The resistor was used to dim the lights, but it could not handle the battery’s voltage, so another one that could handle the voltage was found. In addition to the resistor, a switch was used to power on and off the sign. In future iterations, I would consider painting the back of the sign black to make the lights stand out brighter, as well as using glue to secure the LEDs instead of staples, which obsure view and adds a degree of risk. Finally, I would use a transformer to allow the sign to be plugged into a wall instead of a battery, which would require replacing.

febuary 2026